Chain Conveyor

Backed by the profound experience of the industry, we are engaged in manufacturing and supplying Chain Conveyor. The range of conveyor offered by us comprises Forging Chain Conveyor. These conveyors are manufactured in accordance with industry laid guidelines and using premium quality material sourced from the authentic vendors of the market. We also offer these conveyors in custom-built range, as per the requirements of the patrons.

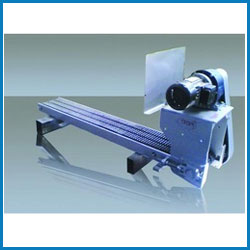

Forging Chain Conveyor

+ Type - Flexible Conveyors

+ Type - Flexible Conveyors

+ Material - Aluminium

+ Material Handling Capacity - 50-100 kg per feet

+ Length - 20-40 feet

We are among the most distinguished organizations engaged in manufacturing and supplying Forging Chain Conveyor. Extensively used to convey forged components from forging press to trimming press, these Forging Chain Conveyors are manufactured by using optimum quality material sourced from the trusted vendors of the market. Complying with industry standards, these conveyors are also used to handle flash from trimming press.

Some of the attributes of these Forging Chain Conveyors are given below:

+ Increased in forge and trim tool life,

+ Productivity increases,

+ Reduces human errors,

+ Easy maintenance.

Specifications of Forging Chain Conveyor:

+ Width of conveyor depends on the dimensions of component to be handled

+ Heavy to Medium sized components can be handled by these type of conveyors

Billet Conveyors

+ Capacity - 50-100 kg per feet.

+ Capacity - 50-100 kg per feet.

+ Belt Width - 10-20 inch

+ Brand - Siddha

+ Material - Stainless Steel

+ Capacity (kg per feet) - 1 to 50

+ Length - 10-20 feet

Billet Conveyors are chain conveyors of low width. Width depends upon the cross section of billets used on the particular press line. These Billet Conveyors are generally used to feed red hot billets to forging equipment.The speed of the billet conveyors ranges from 15 to 50 tr/min depending upon the distance between billet heater and forging equipment.

Benefits of the Billet Conveyors:

+ It assures minimum transfer time of billet from the heater to forging equipment.

+ Being equipment, it assures consistency.

+ By avoiding manual interference, it creates the safe working environment.

+ It can be interfaced with a robot or pick and place for further automation.

+ Simple, compact and easy to maintain.

Billet Conveyor with Accept Reject System

+ Material - Aluminium

+ Material - Aluminium

Type - Flexible Conveyors

Length - 10-20 feet

Billet Conveyor With Accept Reject System are the regular billet conveyors with one or more pneumatically operated flaps for accepting or rejecting hot billets within specified temperature range. The action of pneumatics cylinders is controlled by feedback from pyrometers.

Benefits of the Accept-Reject system:

+ A single flap system feeds billets within the specific temperature range to forging press. System rejects the billet which are not in specifed zone, though it is at higher temperature or lower temperature.

+ Double flap system rejects the higher temperature billets at one flap and lower temperature billet at other flap.Accepted billets are ultimately feed to the forging equipment.

+ High low sorting chute can be used in single flap system to separate under and over heated billet.

+ Under heated billets can be reused in double flap system.

+ Avoids forging of over heated billets.

Chain Type Cooling Conveyor

Generally Cooling Conveyor - Chain Type are not used for controlled cooling purpose, But where cooling rate is very high or forgings are quenched in air blow, chain conveyor can be used. We have designed, manufactured and supplied such type of conveyor. The body temperature of chain could not exceed 80 degree centigrade for better life.

Generally Cooling Conveyor - Chain Type are not used for controlled cooling purpose, But where cooling rate is very high or forgings are quenched in air blow, chain conveyor can be used. We have designed, manufactured and supplied such type of conveyor. The body temperature of chain could not exceed 80 degree centigrade for better life.